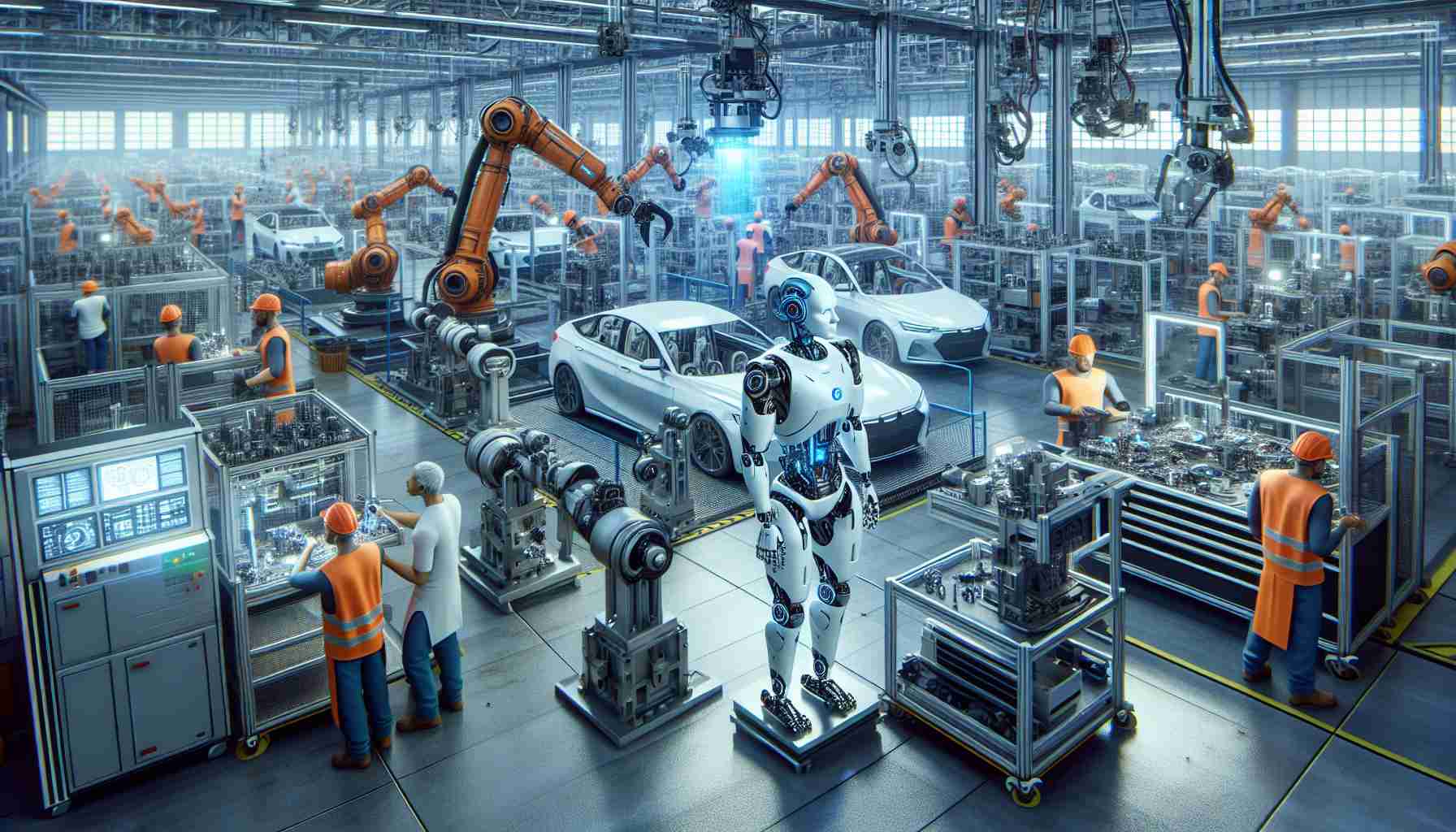

BMW Group is embarking on an innovative journey into the realm of robotic technology. At their Spartanburg facility, the company has initiated a groundbreaking pilot program involving advanced humanoid robots designed for production tasks. Over several weeks, the cutting-edge robot, Figure 02, which hails from a California-based company, successfully performed intricate operations by inserting sheet metal components into the assembly line—a process that demands exceptional dexterity.

This initiative not only enhances production efficiency but also aims to alleviate the physical strain faced by workers engaged in repetitive or awkward tasks. Collaboration between BMW Group and the robotics company is vital, focusing on their safe integration into manufacturing settings. Insights gained from this trial have shed light on the necessary requirements for these humanoid machines to effectively communicate and function within existing systems.

Experts highlight that this development marks a preview of what the future holds for automotive manufacturing. With an emphasis on digitalization, sustainability, and efficiency, the BMW iFACTORY vision is steadily taking shape. The advanced capabilities of Figure 02, including its unmatched processing power, sophisticated sensors, and human-like strength, pave the way for its potential deployment in various physically demanding roles.

While there’s no set timeline for broader application at the Spartanburg plant, the partnership promises ongoing advancements in robot training and integration that could shape the industry for years to come.

BMW’s Bold Leap Into Robotic Innovation: Pioneering the Future of Manufacturing

BMW Group’s Robotic Endeavors

The BMW Group is making significant strides in the integration of robotics into its manufacturing processes, specifically in its Spartanburg facility. This initiative focuses on the use of humanoid robots, like the Figure 02, designed to enhance production efficiency and reduce the physical workload on human workers.

Key Features of Figure 02

Figure 02 boasts advanced capabilities that make it suitable for complex assembly line tasks:

– Dexterity: The robot can manipulate sheet metal components precisely, indicating its potential in handling intricate assembly functions.

– Processing Power: Equipped with high-performance computing capabilities, Figure 02 can process information and adapt to changing tasks in real-time.

– Sophisticated Sensors: These allow for enhanced spatial awareness, enabling the robot to operate safely alongside human workers.

Benefits of Incorporating Humanoid Robots

1. Increased Efficiency: By automating repetitive or strenuous tasks, BMW can improve production speed and output.

2. Reduced Worker Strain: Robotic assistance helps alleviate the physical toll on workers, particularly in roles involving heavy lifting or repetitive motions.

3. Enhanced Precision: Robots can perform tasks with a level of accuracy that is difficult for humans to match consistently.

Use Cases in Automotive Manufacturing

The deployment of humanoid robots like Figure 02 presents various use cases within the automotive sector:

– Assembly Line Operations: Robots can take over tasks such as component installation and quality inspection.

– Material Handling: Humanoid robots can assist in transporting heavy parts throughout the facility.

– Collaboration with Human Workers: The robots can complement human efforts, allowing workers to focus on more complex problem-solving tasks.

Challenges and Limitations

However, the integration of humanoid robots in manufacturing does come with challenges:

– Safety Concerns: Ensuring that robots can operate safely alongside humans requires rigorous testing and protocols.

– Training and Adaptation: Developing robots that can learn and adapt to the manufacturing environment takes significant time and resources.

Market Trends and Future Predictions

As the automotive industry moves towards increased automation, the collaboration between BMW and robotics companies signals a trend expected to grow. Analysts predict that:

– Increased Adoption: More manufacturers will likely invest in robotics to maintain competitiveness in a rapidly evolving market.

– Advancements in AI: Future iterations of humanoid robots will incorporate more sophisticated AI, enabling smarter decision-making and task prioritization.

Security Aspects

With the implementation of robots in manufacturing, security protocols become crucial. Companies must ensure:

– Data Protection: As robots collect and analyze data, safeguarding this information against cyber threats is paramount.

– Operational Security: Developing stringent access controls for robotic systems to prevent unauthorized access or tampering.

Conclusion

BMW Group’s innovative utilization of humanoid robots like Figure 02 represents a transformative step in the automotive manufacturing landscape. As they continue to test and refine these technologies, the industry’s future could see a seamless blend of human and robotic collaboration, redefining workplace dynamics in manufacturing.

For further insights into the evolution of automotive technologies, you can visit the official BMW Group site at bmwgroup.com.